Representative offices ▼

- +86 21 37026221

info@edapm.com

China, Shanghai - +7 (495) 955-52-51

info@sinopharmtech.ru

Russia, Moscow - +375-17-3758899

info@sinopharmtech.by

Belarus, Minsk - +998 90 9467222

info@sinopharmtech.uz

Uzbekistan, Tashkent

Representative offices ▼

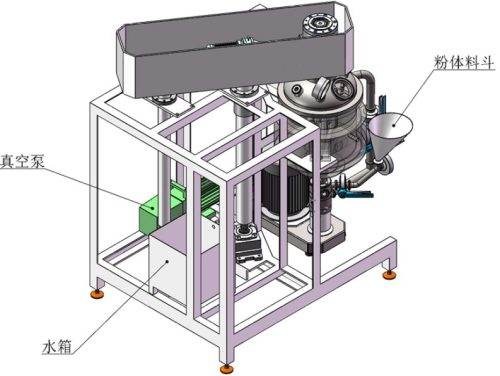

Vacuum homogenising emulsifier with external circulation MC-30

The MC series vacuum homogenising emulsifier consists of an emulsifier, an electrical control system (PLC), a lifting system, an external circulation system, a vacuum system and a frame. Material can be suctioned into the emulsifier directly through the powder and liquid suction port of the control panel; homogenising agitation and paddle agitation can be used separately or simultaneously.

FEATURES.

| Name of equipment | Vacuum emulsifier with external circulation, 30 litres |

|---|---|

| Production capacity | A. Emulsifier design capacity: 30 litres B. Effective working capacity: 5-25 litres |

| Tank lid | Top lid material: SUS316L, thickness 4 mm. The mixing tank lid shall be equipped with inspection port, filling port, compressed air inlet, air filter, LED light, vacuum port, vacuum gauge, spray ball. |

| The tank | Tank is welded and polished to a mirror finish for good roundness. The top flange of the mixing tank is hermetically sealed to the lid with a silicone O-ring. |

| Three-layer structure, fixed tank, conical head at the bottom. Internal material SUS316L, wall thickness 4 mm. Inner tank diameter: φ350 mm, oval head at the bottom. Middle shell, material SUS304, wall thickness 4 mm, diameter: φ400 mm. The shell can be heated by steam, design pressure of the jacket≤0.45 MPa, working pressure≤0.4 MPa. Outer shell, material SUS304, wall thickness 3mm, diameter: φ450mm. Insulating layer of aluminium silicate between the outer layer and the interlayer, effectively preserves heat and prevents burns to the operating personnel. Interior and exterior surfaces are mirror polished |

|

| Stirring system | Anchor type stirring with wall scraper, material SUS316L Motor: three-phase asynchronous motor 380V/50Hz, power 1,1kW Transmission: gearbox with special gear structure Transmission bearing adopts Japanese NSK brand. Output speed 0-86 rpm, frequency converter with digital display, stepless speed adjustment. Anchor type scraper wall paddle, unidirectional mixing, with fixed spoiler blades, the material is quickly and completely mixed, no dead ends. PTFE scraper wall plate, always close to the tank wall, sweeps the coloured material off the tank wall, the materials continue to create a new interface, no dead ends, and heat transfer efficiency is improved. |

| Homogeneous mixing, SUS316L material Motor: 380V/50Hz three-phase induction motor, 3kW power. High-precision stator-rotor homogenising emulsifying head with three-layer gear structure. Built-in bottom with circulation tube, cavity with push impeller effectively moving viscous materials. Circulation tube with glass sight glass and online sampling valve. Homogenising head output speed 0-6000 rpm, frequency converter with digital display, stepless speed adjustment. The collar has one powder suction hole and one liquid suction hole, which can feed the material quickly and ensure its efficiency. Japanese NSK brand is used as the transmission bearing Collective double-sided mechanical seal with organic seal for cooling water of balancing tank. |

|

| Vacuum system | Vane vacuum pump, power: 0.55 kW/380 V. Equipped with SUS304 vacuum buffer tank Vacuum degree -0.09 MPa, can realise the function of vacuum feeding and unloading, and maintain the pressure continuously for a long time. |

| Lifting system | Electric hoist: power 0.55KW/380V, hoist stroke 500mm. |

| Heating system | Steam or electric heating Tiltable plug-in temperature probe, temperature range 0-150℃, intelligent digital display. |

| Cooling system | Jacket water circulation cooling system |

| Discharge method | External circulation pipe outlet, DN32 manual butterfly valve |

| Valve | Manual butterfly valve as standard on the outside of the discharge valve. |

| Safety system | The lid cannot be lifted when stirring has started. Stirring cannot be carried out with the lid raised and lowered; The lid cannot be opened when the pressure in the pot is negative. The frequency converter automatically protects the stirring motor if it is overloaded. There is a safety warning label on the machine body. |

| Control system | The control cabinet panel is made of SUS304 and is equipped with a PLC touch screen. It can be used for start-up, emergency stop, lifting, mixing, homogenisation, heating, vacuum, timing and infinitely variable speed control of the frequency converter. |

| Main technical characteristics | |||

|---|---|---|---|

| Total power of the equipment | 13 kW (not including heating power) | Main material | SUS316L |

| Equipment power supply | 380 V/three-phase/50 Hz | Vacuum degree | -0,09 MPa |

| Equipment composition | Emulsifier/ vacuum/ temperature control | Homogenising structure | Internal and external circulation type |

| Heating method | Steam or electric heating | Control method | Electrical PLC control |

POSITIONS BY DIRECTION

Recently Viewed

SEND A REQUEST